Industry 4.0 is used to describe the digitalisation of both the horizontal and vertical value chain. Processes that were already automated are being transformed once again with increased interconnectivity of computers and systems, the introduction of Big Data analytics, 3D printing and the Internet of Things (IoT).

A combination of all these factors and more are able to create cyber-physical systems such as smart electrical grids, robotic systems and automatic pilot avionics.

What came before?

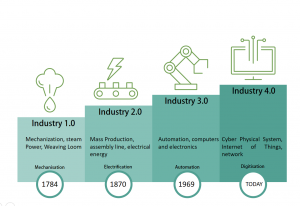

The first industrial revolution is identified as when manual production was overtaken by mechanical processes (steam and water power) which was then surpassed by electrical power and in Industry 3.0, the adoption of the earlier computers and automated systems changed manufacturing once again.

Whilst some commentators feel that Industry 4.0 is just a buzzword, it is clear that manufacturing is once again transforming itself with technological advances in machine learning, hardware capacity and software. Manufacturers are able to identify issues and improvements quicker and find solutions that minimise delay or expense.

What is driving companies to embrace Industry 4.0?

In Germany where the phrase Industry 4.0 was first used, the government decided to target both flexible production and the use of intelligent systems to increase productivity against the perennial issue of global competition.

As overseas manufacturers improve their quality whilst maintaining low prices, it was decided that pushing manufacturers to increase their use of interconnected systems and robotics would offer more personalised customer service as well as lower costs.

How far will this go?

Already companies such as Bosch, Daimler and BASF are adopting this approach. Global companies including Siemens and GE have declared Industry 4.0 is a core part of their identity and so other companies are following their lead.

Ex-CEO of @Intel, Brian Krzanich, has stated he can see a time when intelligent systems predict customer needs, designing and manufacturing products to meet these with little or no human input.

Whilst Industry 4.0 naturally brings benefits in terms of cost-savings and efficiencies, there is the negative effect on jobs and also the need to upskill current workers. Just as importantly, education providers need to work with companies to ensure young jobseekers are properly trained for this new world.

Is your company benefiting from Industry 4.0?

If you are succeeding in the world of IoT, big data or automation, and want to find out how our team of international expansion specialists can help you expand outside your borders profitably, call us for a no-obligation discussion on +44 (0)1234.339966 or send us an email at info@js-group.global and we’ll be in touch.